Call Us

08045479019

Degasser Tablets

Product Details:

- Ph Level Around 9 (1% solution)

- Other Names Boiler water oxygen remover tablets

- Molecular Weight 126.04 g/mol (approx)

- Density 2.63 Gram per cubic centimeter(g/cm3)

- Application Degassing agent for boiler water, removal of dissolved oxygen from feed water, corrosion prevention in water systems

- Poisonous No

- Shelf Life 24 months

- Click to View more

Degasser Tablets Price And Quantity

- INR

- 100 Kilograms

Degasser Tablets Product Specifications

- Round

- Around 9 (1% solution)

- Boiler water oxygen remover tablets

- Industrial grade

- White

- 28321090

- No

- 126.04 g/mol (approx)

- Degasser Tablets

- 2.63 Gram per cubic centimeter(g/cm3)

- Degassing agent for boiler water, removal of dissolved oxygen from feed water, corrosion prevention in water systems

- Sodium Sulphite blend

- Odorless

- Tablet

- Solid

- 24 months

- Inorganic Chemical/Water Treatment Chemical

- Add directly to boiler feed water/storage tank as recommended by manufacturer

- 98

- Odorless

- 33.4C (decomposes)

Degasser Tablets Trade Information

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- 20 Kilograms ton Per Day

- 3 Week

- Yes

- Within a certain price range free samples are available

- All India

Product Description

We have carved a reputed niche in industry for manufacturing and supplying Degasser Tablets. They are required for removing gas from molten aluminum mainly porosity resulted from hydrogen gas. These tablets work by generating nascent chlorine which is highly reactive against hydrogen. They are formulated using perchloroethane that is a white colored crystalline solid having camphor-like odor. Degasser Tablets are also known to remove non-metallics & hard spots and improves mechanical properties of metal.

Features:

-

Environment friendly in nature

-

Helps in reducing the grain size

-

Easy to use with the help of metal plungers

Grain Refiner

We are offering our clients with an appropriately prepared range of degassers that is used for degassing of Aluminum molten metal. Offered as perfectly compressed tablets of chemical powder (mainly Hexachloropethane), our degassers are helpful in compaction and proper release of chlorine gas.

Light alloys normally form coarse and columnar crystals, which depend on pouring temperature and gradients of metal. This coarsed grain structure adversely affects heat process, impairs rolling and extrusion operations which results in low tensile strength. A simple grain refinement treatment produces a mass of minute crystals that eliminate these defects and form a fine grain structure.

Advantages

- Grain Refiner improves mechanical properties of all light alloys.

- It ensures pressure tightness and shrinkage defects are avoided.

- It reduces grain size and thereby aids feeding.

- Rolled and forged products are free from cracking.

- A fine grain structure improves mach inability.

- Grain refiner maintains the consistency of physical properties of metal after heat treatment.

Instructions

When metal temperature reaches 700C, turn off the furnace and allow the temperature to increase upto 740-750C. plunge the recommended quantity of grain refiner to the bottom of the melt. When all the turbulence of grain refining operation stops, stir the metal thoroughly and perform degassing operations and finally dross off before pouring. The grain refiner is a hygroscopic material and in many foundries where it is not carefully handled or stored in open unsealed packets, it will pick up moisture. When such grain refiner is introduced in metal, it may introduce hydrogen gas into the metal. Therefore degassing after grain refining is always recommended.

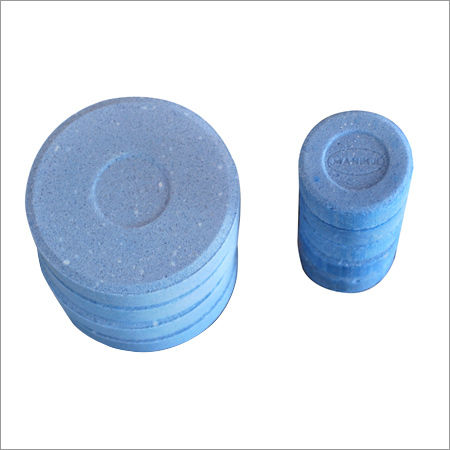

Packing

Grain Refiner are available in the shape of 50 gms. & 250 gms. compact tablet form. The tablets are packed in 20 kgs & 40 kgs Box that is solid enough to withstand shakes and jolts of transportation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+