Call Us

08045479019

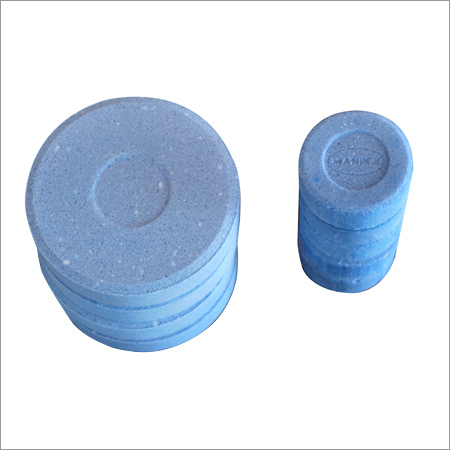

Degasser Furnace Tablets

Product Details:

- Taste Odorless

- Structural Formula Not Available

- Smell Odorless

- Density 2.2 Gram per cubic centimeter(g/cm3)

- Shelf Life 24 months

- HS Code 38109090

- Shape Tablet / Round

- Click to View more

Degasser Furnace Tablets Price And Quantity

- 100 Kilograms

- INR

Degasser Furnace Tablets Product Specifications

- Metallurgical Flux

- White to Gray

- Degassing Tablets

- Added to molten metal for removal of hydrogen and inclusions

- Not Available

- Store in a cool, dry place away from moisture

- High Above 98%

- Solid tablet

- Industrial

- Above 600C

- Solid

- Odorless

- Odorless

- Not Available

- Tablet / Round

- No

- 2.2 Gram per cubic centimeter(g/cm3)

- 24 months

- 38109090

- Not Available (proprietary blend)

Degasser Furnace Tablets Trade Information

- 20 Kilograms ton Per Day

- 3 Week

- Yes

- Within a certain price range free samples are available

- All India

Product Description

With a vision to be a pioneer in our domain, we have been engaged in business of manufacturing and supplying Degasser Furnace Tablets. They are used when metal is at highest temperature in the furnace but temperature is falling. These tablets are added to molten aluminum with the help of box plunger or bell according to size of tablet as deep as possible. They are held till the time bubbling ceases. Offered Degasser Furnace Tablets are highly effective degassing and refining agents having the ability to completely remove hydrogen gas.

Features:

-

Prevents formation of pin holes and porosity

-

Enhances the machinability of aluminum alloy

-

Works by generating chlorine

Degassers

We are offering our clients with an appropriately prepared range of degassers that is used for degassing of Aluminum molten metal.

This degassers gives the utmost degassing effect. It is used for all types of Aluminum and its different types of alloys. The application rate for this type of degasser is also about 0.2 %.

Instructions

After attaining the required metal temperature, shut off the furnace to have better degassing effect at falling temperature. DEGASSER tablet is to be slightly heated before use after removing the wrapper precaution is to be taken to avoid exposure of tablet to the atmosphere as it may pick up the moisture. Push the dross a little aside and plunge the recommended quantity of DAGA DEGASSER using a preheated perforated bell plunger to the bottom of the melt. As soon as the bubbling stops remove the plunger after rabbling & skim off the dross.

Advantages

The use of Degasser is quite simple it does not require any special tool as equipment. It removes hydrogen gas, oxides and other impurities from the melt which results in superior finishing of the metal and avoids pinholes in the castings.

Packing

DAGA DEGASSERS are available in the shape of 50 Gms. & 250 Gms compact tablet form. The tablets are packed in 20 kgs & 40 kgs Box that is solid enough to withstand shakes and jolts of transportation.

Advanced Hydrogen and Inclusion Removal

Degasser Furnace Tablets are engineered for effective gas and impurity elimination in molten metals, thereby improving casting quality and process efficiency. Their solid, round design ensures precise dosing and homogenous distribution during furnace operations. This results in metals with fewer defects and improved mechanical properties, making them a vital asset in industrial metallurgy.

Safe and Simple Application

These odorless, non-toxic tablets streamline handling during production. Their robust physical form ensures safe use while minimizing environmental and operator impact. Simply add the recommended amount to the molten metal bath as specified by process protocols. Their stability at high temperatures and proprietary composition ensures consistent performance.

FAQs of Degasser Furnace Tablets:

Q: How are Degasser Furnace Tablets applied in the metallurgical process?

A: Degasser Furnace Tablets are introduced directly into the molten metal after reaching the desired temperature. The tablet disperses throughout the bath, facilitating removal of hydrogen and inclusions, and enhancing the final metal quality.Q: What metals benefit most from degassing tablets?

A: These tablets are primarily used for non-ferrous metals such as aluminum, though they can be utilized in various foundry applications requiring impurity and gas removal to optimize material properties.Q: When should Degasser Furnace Tablets be added during the melting process?

A: Tablets should be added once the molten metal has reached operating temperature, before casting or alloying steps, to ensure maximum effectiveness in impurity reduction.Q: Where should degassing tablets be stored for maintaining quality?

A: To preserve their efficacy and prolong shelf life, the tablets must be stored in a cool, dry location away from moisture, following standard industrial storage guidelines.Q: What safety measures should be considered when handling these tablets?

A: Degasser Furnace Tablets are non-poisonous and odorless, but general protective equipment such as gloves and safety glasses are recommended during handling to avoid contact with molten metal.Q: What is the main benefit of using Degasser Furnace Tablets?

A: Their primary benefit is the significant reduction of hydrogen content and non-metallic inclusions in molten metal, leading to superior casting quality and improved productivity in manufacturing processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+