Call Us

08045479019

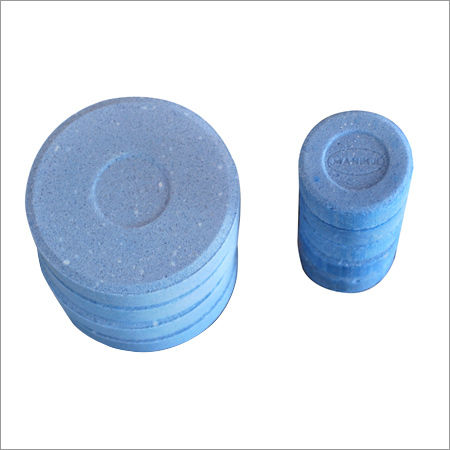

Aluminium Casting Degassing Tablets

Product Details:

Aluminium Casting Degassing Tablets Price And Quantity

- INR

- 100 Kilograms

Aluminium Casting Degassing Tablets Trade Information

- 20 Kilograms ton Per Day

- 3 Week

- Yes

- All India

Product Description

Aluminium Casting Degassing Tablets

Product in Brief

Aluminium & its alloys are susceptible in absorbing gas even when the best-controlled melting processes are performed. There are many factors which cause absorption of Hydrogen gas like water vapour from atmosphere, damp scrap, clamp tools, prolonged holding of metals etc. During the process of casting these unwanted gases release suddenly in the form of bubbles, which are trapped in the metal, and finally the development of pinhole porosity in the cast product occur. It is therefore necessary to remove the unwanted gas from the melt prior to pouring.

DAGA DEGASSERS SP-II (Red)

are formulated to remove hydrogen gas, oxides and other impurities from the melt which results in superior finishing of the metal and avoids pinholes in the castings It is used for all types of Aluminum and its different types of alloys. The appliCation rate for this type of degasser is about 0.2

Instructions

After attaining the required metal temperature, shut off the furnace to have better effect at falling temperature. DEGASSER or DGR tablet is to be slightly heated before use after removing the wrapper. The precaution is to be taken to avoid exposure of tablet to the atmosphere as it may pick up the moisture.Push the dross a little aside and plunge DEGASSER or DGR using a preheated perforated pIUnger to the bottom of the melt. As soon as the bubbling stops remove the plunger after rabbling, skim off the dross.

Packing

DAGA DEGASSERS AND DAGA DGRs are available in the shape of 50 Gms. & 250 Gms, packed in 25 kgs, 30 kgs & 40 kgs Boxes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+