Call Us

08045479019

Tundish Covering Compound DAFEX 21

Product Details:

- Purity >95%

- Molecular Formula Mixture (Complex Silicate)

- Form Free flowing Granules

- Solubility Insoluble in water

- Taste Odorless & Tasteless

- Melting Point 1200C - 1300C

- Other Names Insulating tundish covering powder

- Click to View more

Tundish Covering Compound DAFEX 21 Price And Quantity

- 30 INR

- 100 Kilograms

Tundish Covering Compound DAFEX 21 Product Specifications

- Odorless & Tasteless

- Insoluble in water

- 1200C - 1300C

- Tundish Covering Compound DAFEX 21

- Insulating tundish covering powder

- Granular

- To prevent heat losses, oxidation and contamination during tundish operation

- Odorless

- Standard Industrial Grade

- 38160000

- Steel tundish covering during continuous casting

- >95%

- Alumino Silicate Based Compound

- Refactory, Non-Hazardous

- Mixture (Complex Silicate)

- Free flowing Granules

- Granular Tundish Covering Compound

Tundish Covering Compound DAFEX 21 Trade Information

- 20 Kilograms ton Per Day

- 2 Week

- All India

Product Description

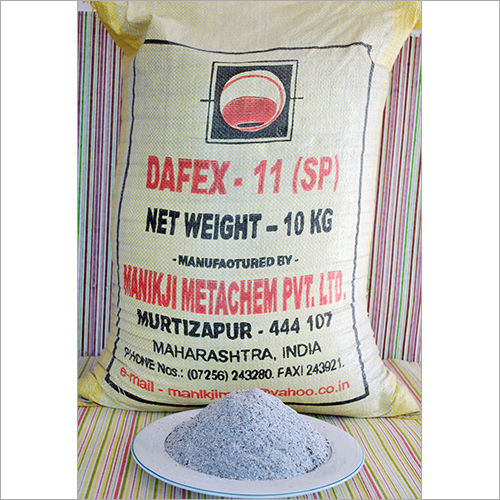

Tundish Covering Compound DAFEX 21

Product In Brief-

This compound is Specially formulated for use as a ladle insulating cover in conventional casting . It acts as best insulator and is specially recommended for duplex board. Being a neutral cover, it can be used for Supersilica as well as Magnesite board also.

DA FEX-21 ( SP ). IS an extremely efficient insulator, as soon as it is poured on molten metal, it expands almost five times and spreads immediately. If covers entire metal surface of the ladle and Tundish within few seconds. It prevents hard crest formation on the ladle wall and reduces skulling near nozzles. The heat losses are negligible. Ladle dumps out clean metal, with no metal adhering to the refractory lining. There is no need to superheat metal prior to handling, thus extending furnace and, ladle refractory life, while contributing to overall operating efficiency and improved metallurgical properties. The exothermicity is maintained throughout the process.

It is recommended to use this compound 2 kgs. per ton of molten metal.

PACKING

The material is packed in 10 kgs. HDPE woven sack.

DAFEX-ZI is also an Alumina based neutral cover, recommended for duplex board & also it may be used in Super Silica d: Magnesite boards. This product doesn't have any expansion property but it also spreads immediately.

Superior Insulation and Protection

DAFEX 21s very low thermal conductivity ensures efficient heat retention in the tundish during continuous steel casting. The compounds excellent fire resistance and insulating properties minimize oxidation and contamination, significantly improving metal quality and yield.

Versatile, Eco-Friendly Usage

This tundish covering compound is environmentally safe, non-toxic, and odorless, providing a safe solution for steel manufacturers. Its compatibility with most tundish lining refractories and its adaptability to various processes make it widely applicable across steel plants.

Ease of Storage and Application

DAFEX 21 retains its insulating properties for up to 12 months when stored in a cool, dry area, protected from moisture. The compounds free-flowing, granular form in 25kg HDPE bags ensures easy handling, transport, and consistent application during steel casting operations.

FAQs of Tundish Covering Compound DAFEX 21:

Q: How should Tundish Covering Compound DAFEX 21 be stored for maximum shelf life?

A: DAFEX 21 should be stored in a dry and cool area, well protected from moisture. When kept in these conditions, it maintains optimal performance for up to 12 months.Q: What is the main application of DAFEX 21 in steel production?

A: This compound is primarily used as a tundish covering agent during continuous casting, providing insulation to prevent heat loss, oxidation, and contamination of molten steel.Q: When is DAFEX 21 applied during the casting process?

A: It is applied after molten steel has been poured into the tundish, forming a protective layer on the surface to maintain temperature and purity throughout the casting operation.Q: Where can DAFEX 21 be used effectively?

A: DAFEX 21 is suitable for steel plants and foundries utilizing tundish systems in the continuous casting of steel. Its versatility allows it to be used with most tundish refractory linings.Q: How does using DAFEX 21 benefit the steel casting process?

A: By minimizing heat loss and preventing both oxidation and contamination, DAFEX 21 improves casting yield, enhances steel quality, and provides an eco-friendly, safe operational environment.Q: What are the handling and packaging guidelines for DAFEX 21?

A: The compound comes in 25 kg HDPE bags or custom packaging as required, in free-flowing granular form, ensuring easy handling and application during use.Q: Is DAFEX 21 environmentally safe and user-friendly?

A: Yes, DAFEX 21 is non-poisonous, non-toxic, odorless, and environmentally safe, adhering to industry standards for both safety and performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+